Excitement About Tin Roofing

Table of ContentsTin Roofing Things To Know Before You Get ThisExcitement About Tin RoofingSome Known Questions About Tin Roofing.The smart Trick of Tin Roofing That Nobody is Talking About

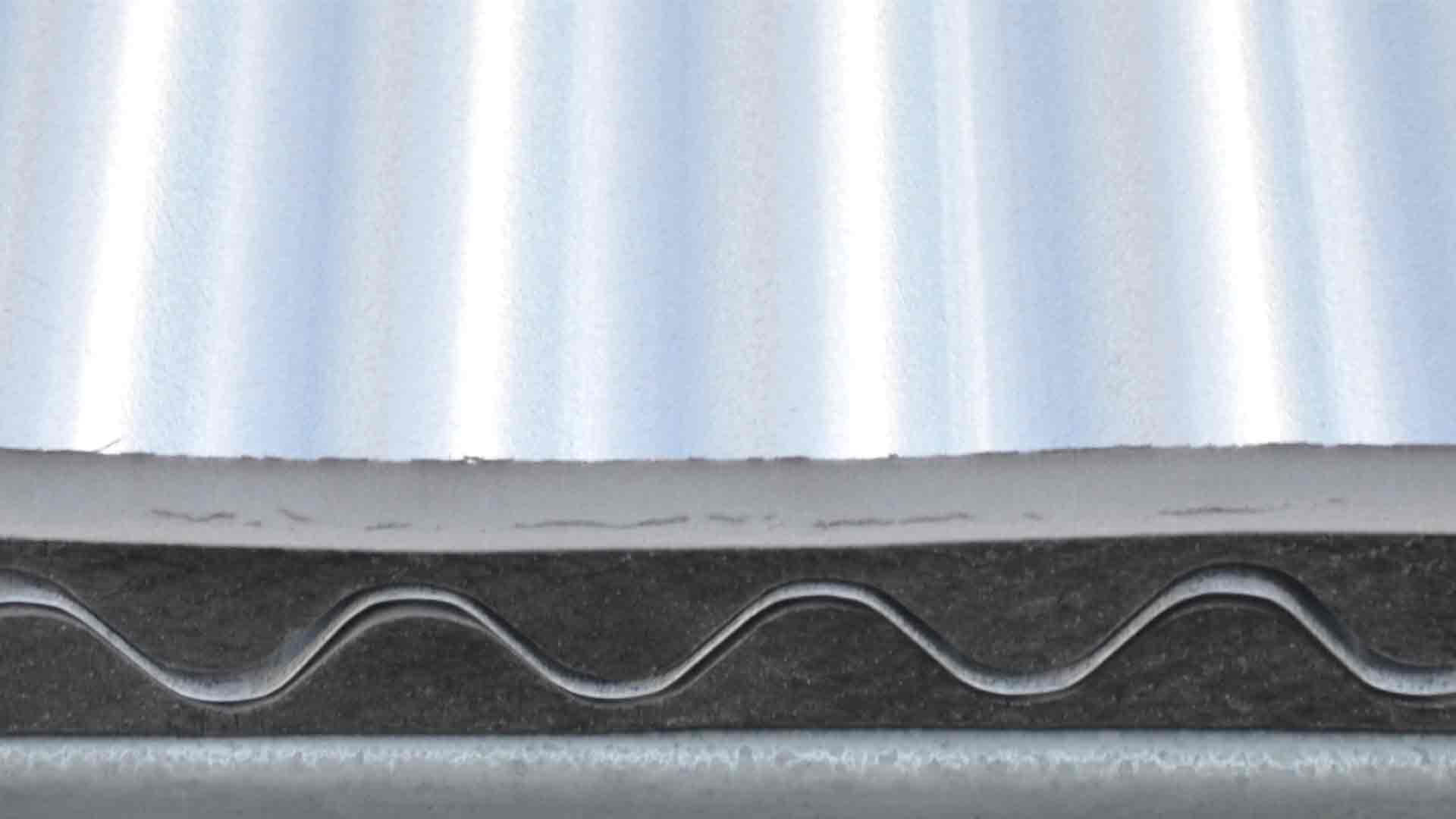

With its sleek, modern-day look, metal panel roof was our initial choice for the Trip. It has no visible joints and also is upkeep free also a light rain will certainly clean leaves and sticks off the roofing. Also better, it will not grow moss and algae in the color of the Wisconsin timbers. Action 3 Prior to you install the trim, cut and bend the leading end to cover it around the edge. Make a series of one-inch cuts with air travel cuts at each bend to develop tabs.In warmer climates, the eave is connected prior to the underlayment. In northern Wisconsin, where ice dams are typical, we set up these atop the underlayment to secure the whole roof from dams.

Cut the lower hem of the underlapping trim at an angle. After setting up the underlapping trim, apply sealant on top.

Initially, make a mark along the eave three feet (or any type of several of three) from the edge. At that mark, determine four feet (or the very same multiple of 4) toward the ridge. From the original corner, procedure 5 feet (or the same multiple of 5) as well as mark where it intersects the second mark.

Some Known Details About Tin Roofing

Run a grain of sealant on top of the closure strip, after that set your panel so it overhangs beyond the eave by one inch. Adjust the panel so any kind of dimension from it to the reference line coincides at the top and also base. Family Members Handyman Step 8 Fastening the panels ideal is the crucial to a leak-proof roofing.

Use the rise to calculate the incline factor using the formula (rise2 + run2) run, where the run is the width that area of the roofing from front to back. Finally, multiply size by size by the incline aspect to discover the location of each section of roof covering. Total the location of each section to locate the complete location of your roofing.

Now it's time to include your metal roof panels. Always begin at the part of the roofing with the longest distance in between the peak and also the eaves. Secure each panel in position using neoprene washing machine head screws, spaced regarding 12 inches (30 centimeters) apart along the entire panel. Each new panel should overlap with the one alongside it by at the very least 1 inch (2.

— Cloud Links (@ldcloudlinks) February 13, 2023find this

When the entire roof covering is covered, add the blinking, which is a series of metal strips that cover the joints where the different areas of the roof meet. You'll need to reduce the ends of the strips at the proper angle prior to mounting them. Connect them with 1 to 2 rows of screws, depending upon just how broad they are - Tin Roofing.

The Facts About Tin Roofing Revealed

Below, we've laid out all the necessary info you'll require to improve your existing roofing and also a detailed overview for steel roof covering setup. Discover Regional Roof Providers Free approximates based upon your roof covering, no phone call required Generally expenses in between $1$25 per square foot Get your quote in 30 seconds As with any home improvement, you'll need the right tools resource as well as materials for the task.

They are as adheres to: Different types of steel roof covering will come with diverse cost factors. 25$4. 75$20 $25$1.

Before setting up, you should additionally take into consideration wind direct exposure as well as your area environment, as this will affect the amount of nails you use. You can substitute these for metal-to-wood screws for particular metal roof covering applications, such as corrugated roof installation (Tin Roofing). We recommend zinc-plated roofing screws, which come in a selection of shades to match your precise roofing system shade.

All About Tin Roofing

This leak-proof base layer goes over existing roof covering outdoor decking or substrate and also will have a glue backing. Both butyl tape and also caulk will have their usages. When joining two corrugated steel panels with each other, you need to use a strip of double-sided butyl tape at the overlap factor to effectively seal out the aspects.

While setting up a metal roofing on your very own will certainly not include the normal warranties or convenient procedure of working with a professional roofer, it is still an excellent selection for most house owners. They can last much longer than their asphalt tile equivalents and will develop an even more energy-efficient residence as a result of fuller securing from the click here for more info components.